4. Compliance with Regulations

Many industries are subject to regulations that require them to maintain a safe and healthy work environment for employees. Downdraft tables can help businesses comply with these regulations by effectively capturing and removing harmful contaminants. This can help businesses avoid fines and penalties for non-compliance and maintain a positive reputation with regulators and customers.

5. Increased Productivity

By creating a safer and healthier work environment, downdraft tables can also help increase productivity. When workers feel safe and comfortable, they are more likely to focus on their tasks and perform at their best. Additionally, by reducing the risk of health issues, downdraft tables can help reduce absenteeism and turnover, ensuring that businesses have a reliable and productive workforce.

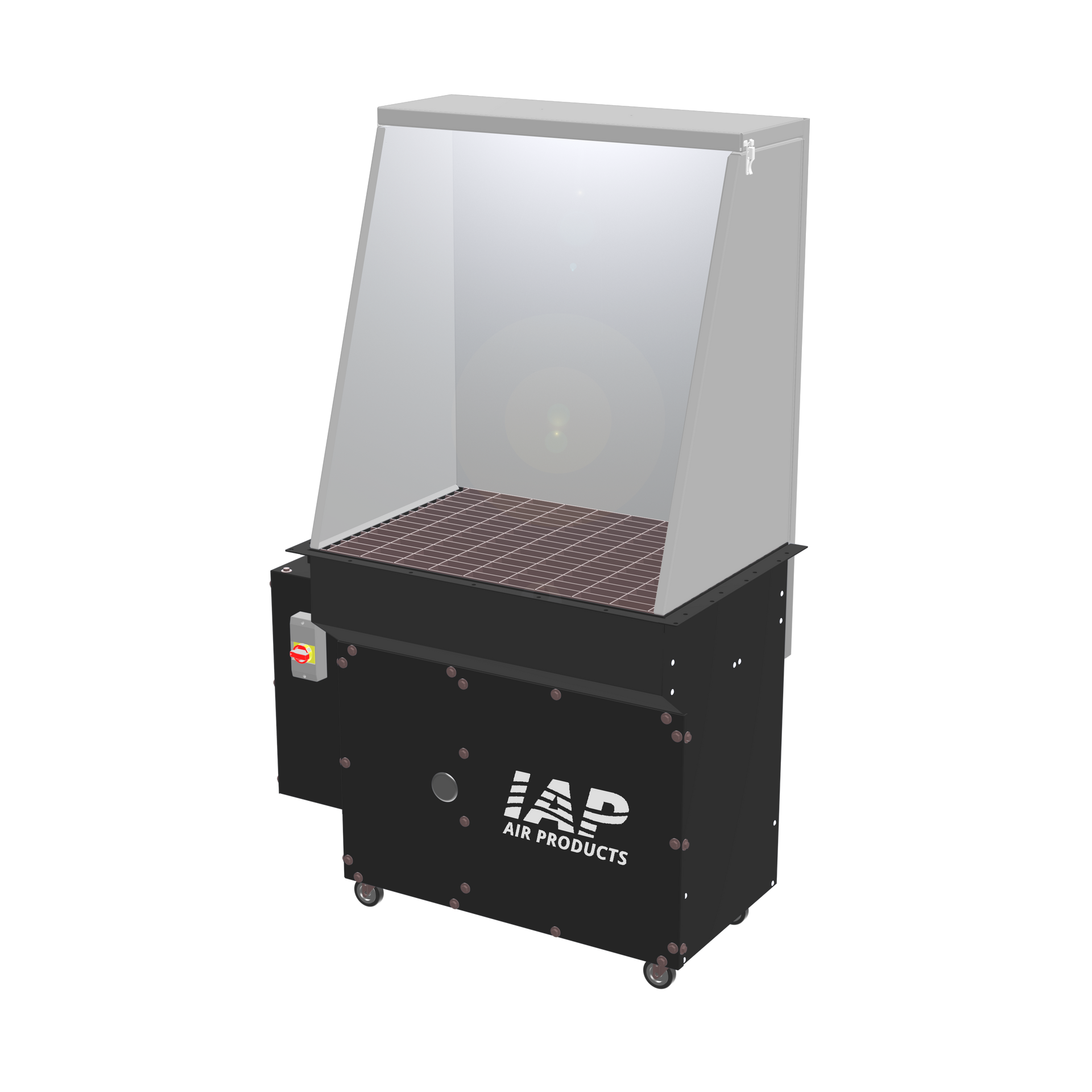

6. Versatility

Downdraft tables are versatile and can be used for a variety of applications, including welding, grinding, sanding, and cutting. This makes them a valuable investment for businesses that need to perform multiple tasks in their operations. Additionally, downdraft tables can be customized to meet the specific needs of different industries and applications, ensuring that they provide optimal performance and efficiency.

Conclusion

In conclusion, downdraft tables offer a range of benefits for businesses that perform welding and grinding operations. From improving air quality and worker safety to protecting equipment and ensuring compliance with regulations, these tables can help businesses create a safer, healthier, and more productive work environment. With their versatility and customizable features, downdraft tables are a valuable investment for businesses looking to enhance their operations and protect their employees and assets.