Home | Products

FUME EXTRACTOR PRODUCTS

IAP Air Products sets the standard for our industry. The IAP Air Products line of fume extractors and fume extractor products reflects our increased focus on providing our customers with products that effectively capture harmful particulates, protecting their employees. We will remain the leader by continuing to help our customers meet their needs with durable and reliable fume extractor equipment. IAP Air Products has the best distribution and product support system in the industry. Our Warehouse is centrally located in Middle Tennessee and stocked with product to fulfill your needs. We can ship within 24 hours of your order on these fume extractor products. Our Sales Team is not only knowledgeable about the fume extractor products we offer and their applications, but also have extensive freight knowledge to help with shipping solutions.

MODELS

WhY are WELDING fume extractORS SO IMPORTANT?

In welding operations, workers are in a daily contact with harmful weld fume particulates because weld fume is made up of 30 to 80 percent submicron-sized particles. The fume consists of a complex mixture of metals and metallic oxides originating primarily from the filler metal but can also include the base metal and surface contaminants such as dirt, scale or lubricants. With fumes being of submicron-sized particles, this means that most of these particles are respirable (entering the lungs), which makes it critical to have reliable, high performance welding fume extractors and fume extractor products that collect the fume before it reaches your welder’s breathing zone.

Regardless of the system, capturing fumes at the source is the only effective way to eliminate the health hazard. Welding fumes affect the welder´s health conditions, end product quality and production equipment. It reduces capacity, disturbs the production, and decreases the bottom-line result. A prosperous business demands sound, and safe workplaces.

IAP offers a full line of welding fume extraction and collection equipment that can be utilized to safely control welding and thermally generated fumes. Some of the products our application engineers can assist you with include: source capture welding fume extraction arms, mobile weld fume extractors with filtration, portable weld fume collectors, welding booths, vehicle exhaust systems, and ambient air cleaners.

The following is a review of the methods of collection:

Source Capture

Whenever possible, capturing and controlling weld fume at the source is the recommended approach. Source capture involves utilizing various types of hoods to extract the fume at or near the generation source to protect the worker and prevent the fume from migrating elsewhere in the facility. Source capture is the most effective means of capture and requires the least amount of energy and initial investment to accomplish. Source capture can be accomplished utilizing fume extraction arms or local fixed hoods.

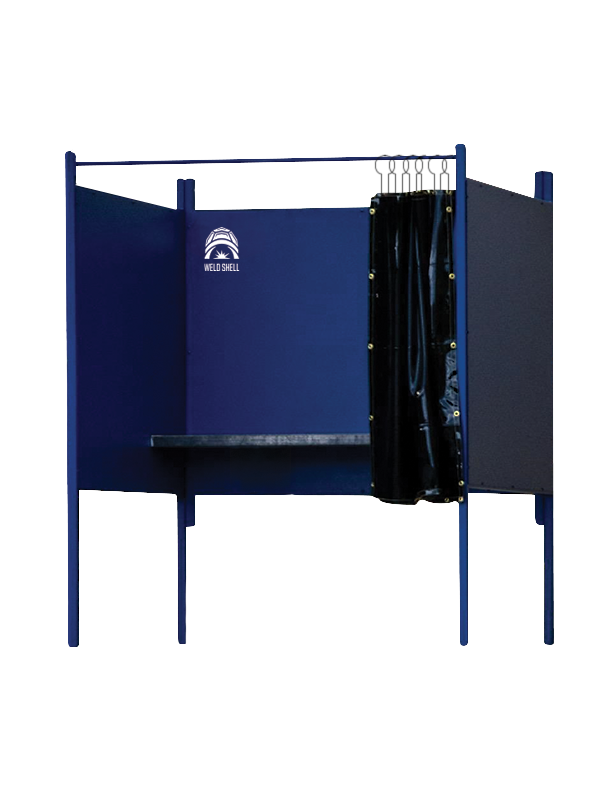

Containment

Different than source capture in that it does not capture directly at the source, containment isolates the welding process from the rest of facility and protects the contained area. Containment can be used where hoods are not practical next to the welding, but the process can be isolated from other parts of the factory. An example would be a partitioned area (weld curtain) or booth with ventilation.

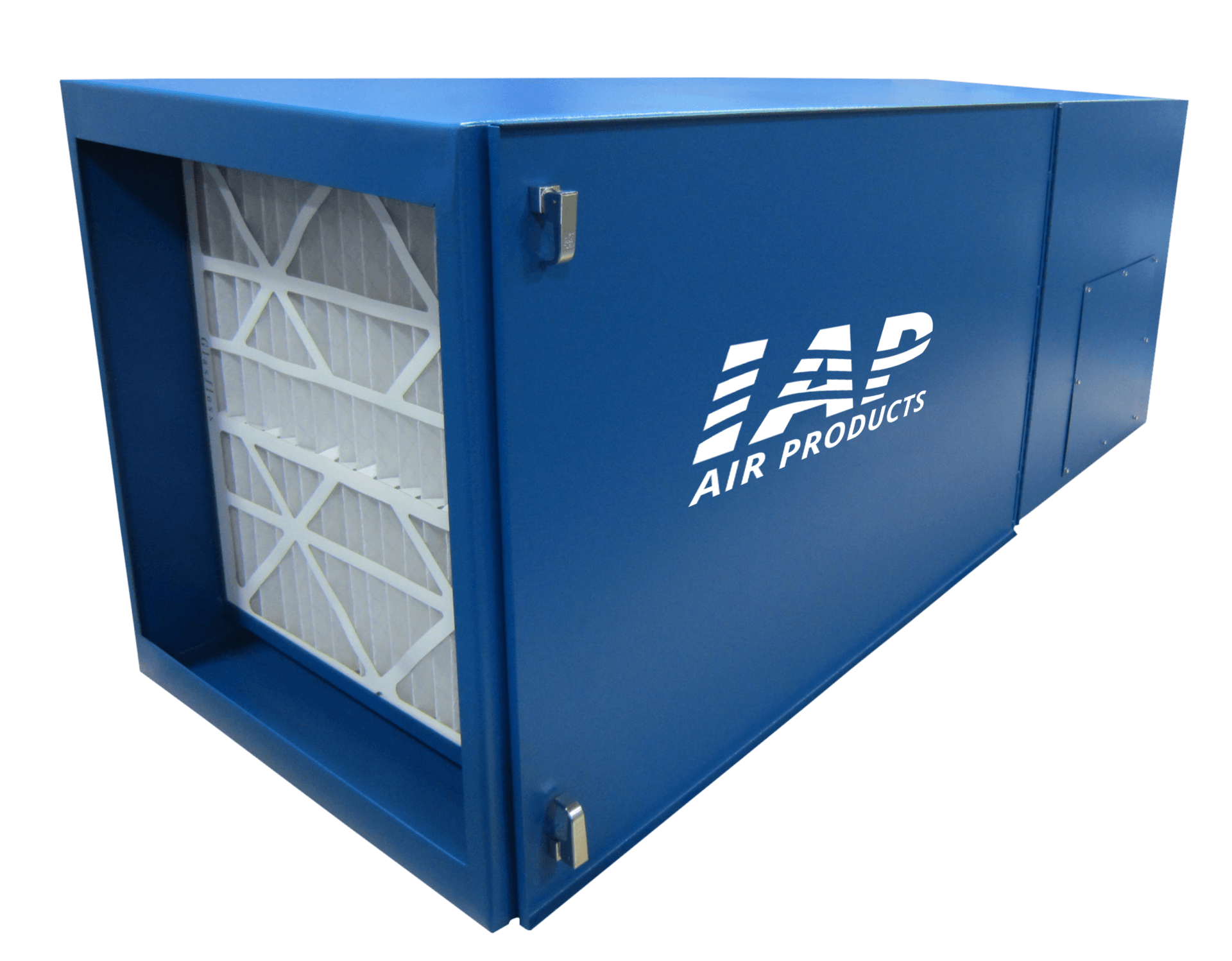

Ambient Air Cleaners

When source capture or containment is not possible, filtering ambient air can be utilized to control the fume concentrations to an acceptable level. Ambient systems are common in welding processes with large components or when there are overhead obstructions such as overhead cranes that make use of weld fume extraction arms or local hoods impractical. Ambient systems can be configured in a “push-pull” arrangement to push the fume away from the worker’s breathing zone and toward the collection points where the fume is then pulled into the collection system. This arrangement can improve fume control and reduce operational costs.