Innovations in welding fume extraction arm design

Fume extraction for workplace safety and environmental protection

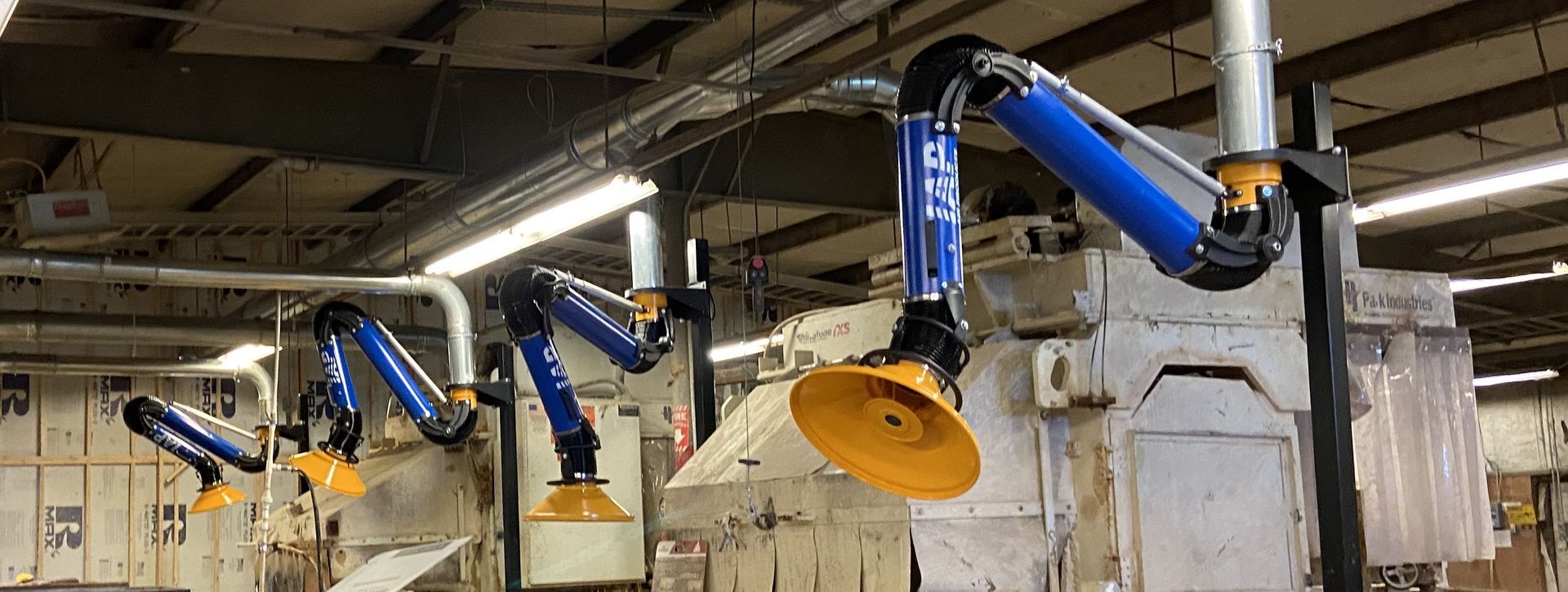

Fume extraction is a critical aspect of workplace safety and environmental protection, particularly in industries where hazardous fumes are generated. Fume arms, also known as welding fume extraction arms or articulating arm, play a crucial role in capturing and removing harmful airborne contaminants. In recent years, there have been significant advancements in fume arm design, driven by the need for more efficient, versatile, and user-friendly solutions. This article explores some of the latest innovations in welding fume extraction arm design and their implications for the future of fume extraction.

1. Flexible and Articulated Arms:

Traditionally, welding fume extraction arms were rigid structures that could be adjusted manually to a limited extent. However, modern fume arms feature flexible and articulated designs that offer greater maneuverability and reach. These arms can be easily adjusted in multiple directions, allowing users to position them precisely where needed. This flexibility is particularly beneficial in environments with limited space or complex layouts, such as laboratories or manufacturing facilities.

2. Enhanced Capture Efficiency:

One of the key challenges in fume extraction is ensuring that all hazardous fumes are effectively captured and removed. To address this, manufacturers have developed fume arms with improved capture efficiency. These arms feature over-sized hoods or nozzles that create a high-velocity airflow, effectively capturing fumes at the source. Some fume arm models also incorporate advanced filtration systems to remove particulate matter and other contaminants, further enhancing their effectiveness.

3. Ergonomic and User-Friendly Features:

In addition to technical advancements, modern welding fume extraction arms also prioritize user comfort and convenience. Many models feature ergonomic designs with adjustable height and reach, allowing users to work comfortably without straining or stretching. This is best achieved with external joints that are easily adjusted as well as balancer springs to help keep the weight of the arm even distributed.

Conclusion:

Innovations in welding fume extraction arm design are transforming the landscape of fume extraction, offering more efficient, versatile, and user-friendly solutions. Flexible and articulated arms, enhanced capture efficiency, ergonomic features, and sustainability are some of the key trends driving these advancements. As technology continues to evolve, we can expect further innovations that will shape the future of fume extraction and contribute to safer and healthier workplaces.

SHARE THIS POST