Why Choose Stainless Steel Welding Fume Extraction Arms?

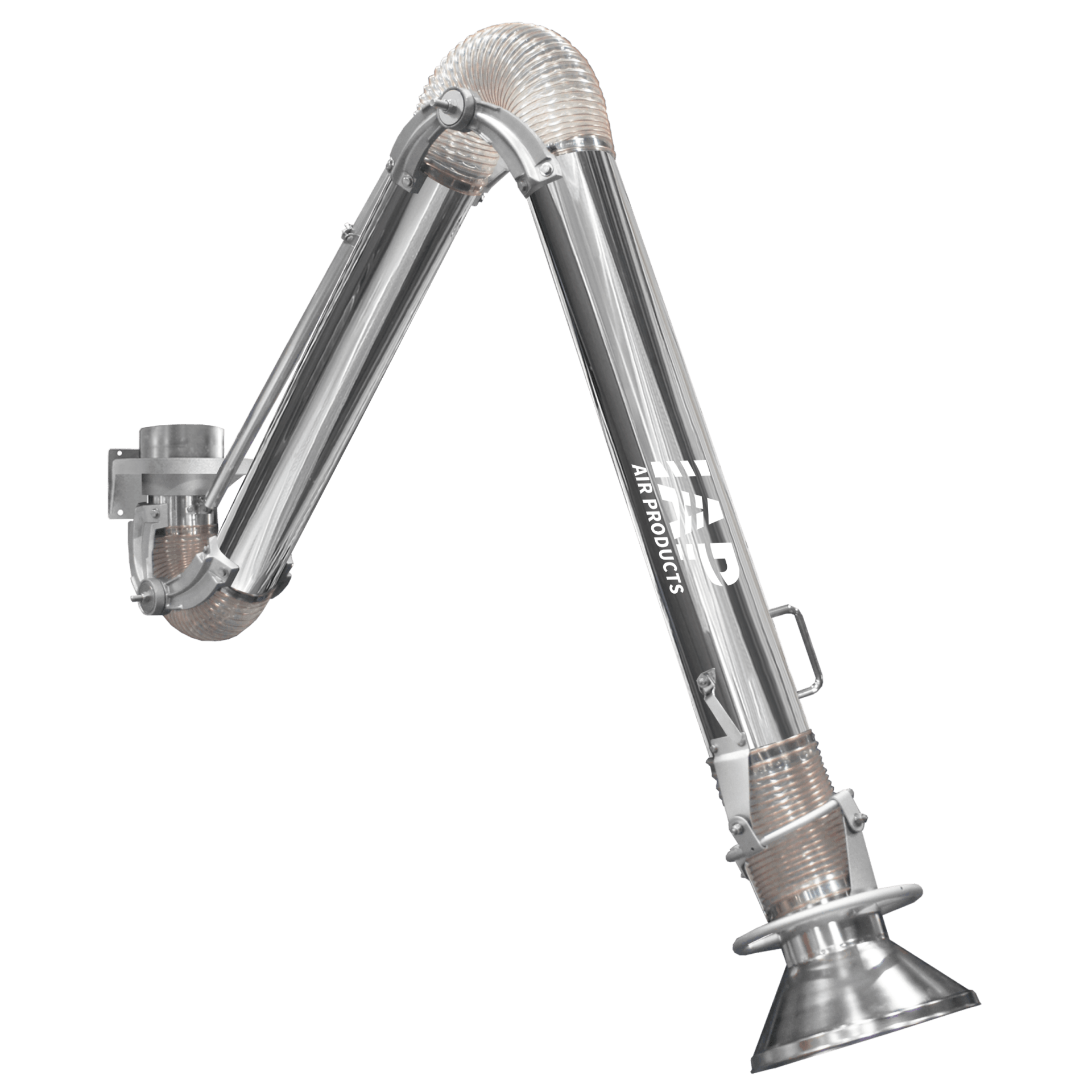

Stainless Steel Fume Extraction Arms

There’s no doubt that source capture is the best way to remove any fume, mist, or dust particulate problems that you may be facing. While there are various types of hoods to use for source capture, welding fume extraction arms are an increasingly popular choice for this. While most people correlate fume extraction arms with the welding industry (and rightly so), there’s a few more industries that have just as much of a need for this style of extraction arm, such as: Pharmaceutical Facilities, Food Processing Facilities, or really any facility that must abide by FDA guidelines.

So, what’s so special about the fume arms for these applications? This is a very important question because not just any welding fume extraction arm will work. When you’re looking for an extraction arm to meet FDA or wash-down applications, you want:

- Stainless Steel/Anodized Aluminum Construction (For Cleanliness and water resistance)

- Incorporation of clear, electrically conductive, FDA flex hose.

- High quality construction (These arms are not cheap so you want something that will last!)

- Easy to clean

- Optional grounding or ATEX Versions

The last bullet point is a very serious one to consider. If you are working in an application that is a clean room or has a high risk of explosive dust, you don’t want to settle for anything less than an ATEX Rated arm. This means that the extraction arm comes with a certified rating that it will be grounded (or double grounded) so that it will not carry a static charge that will ignite the dust. ATEX Rated arms are very expensive but are worth the cost (and most likely required) for safety if you are working in an explosive environment.

However, if you are not working in a clean room or highly explosive environment, it’s likely that you may still want your arms grounded (even if it doesn’t come with an ATEX Rating) just for the extra safety factor! This can either be done by some manufacturers or by the customer with some grounding cables, stainless steel hardware, and an Ohm’s reader.

Lastly, Stainless Steel Extraction Arms are an INVESTMENT that can help ensure the high quality of your product and cleanliness of your shop. Make sure you find someone who has experience with Stainless Steel Extraction Arms.

For questions regarding stainless steel fume extraction arms, contact sales@iap-airproducts.com.

SHARE THIS POST