The Ultimate Guide to IAP Stainless Steel Fume Extraction Arms

Features, Benefits, and More

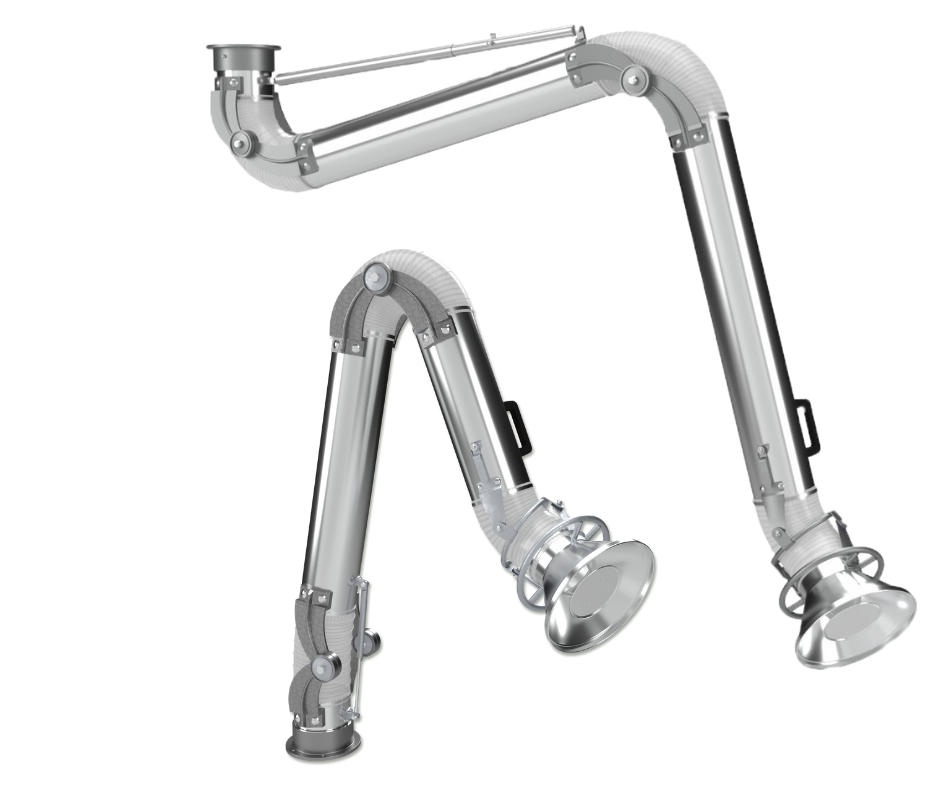

In industries like pharmaceuticals, food production, and beyond, ensuring a clean and safe working environment is crucial. IAP Stainless steel fume extraction arms offer an optimal solution for managing fumes, dust, and airborne particles in various environments. These durable, easy-to-use systems are essential in maintaining air quality and meeting stringent safety standards.

Key Features of IAP Stainless Steel Fume Extraction Arms

1. FDA-Approved Stainless Steel Construction

Made from high-quality 304 stainless steel, these extraction arms are designed to meet rigorous standards in FDA-regulated industries. Their corrosion-resistant design ensures durability, even in harsh environments, making them ideal for areas that require frequent cleaning and disinfecting.

2. Versatile and Adjustable Design

IAP Fume extraction arms are highly flexible, allowing users to reposition them easily to capture contaminants from various angles. This adaptability makes them ideal for a range of tasks, from laboratory work to industrial applications. The extraction arms can extend, retract, and bend, offering customized extraction solutions for different operations.

3. Efficient Fume and Dust Capture

These fume extraction arms efficiently capture airborne contaminants, including dust, fumes, and vapors, right at the source. Their strategically designed hoods and flexible tubing work together to contain potentially harmful substances. Combined with high-quality filtration systems, they help reduce exposure to harmful particles, improving workplace safety and air quality.

4. Regulatory Compliance

Whether in pharmaceuticals, food processing, or manufacturing, these fume arms meet industry regulations, helping businesses maintain compliance with safety and air quality standards. By ensuring proper extraction and filtration of fumes and dust, they also help maintain a clean and safe environment for workers.

Key Applications Across Industries

1. Pharmaceutical and Chemical Manufacturing

Used to capture toxic vapors, dust, and airborne particulates during the preparation of pharmaceutical ingredients and chemical processing. They also play a crucial role in maintaining cleanroom environments by preventing powder contamination, which could affect both product quality and regulatory compliance.

2. Food Production

In food processing plants, fume extraction arms are used to capture airborne flour dust, powdered additives, and fumes from cooking or baking processes. This not only ensures the safety of workers but also helps maintain the quality of food products by preventing contamination from airborne particles.

3. Laboratories

In research and development labs, these fume arms efficiently extract fumes and vapors from chemicals, solvents, or reactions. This creates a safer environment for researchers working with volatile or hazardous materials and ensures that toxic substances are removed before they can spread.

4. Environmental Remediation

Used in hazardous waste sites or during environmental cleanup operations, these fume extraction arms help capture dust and vapors that could pose a threat to workers and the surrounding environment. This makes them essential for industries involved in environmental remediation and waste management.

Benefits of IAP Stainless Steel Fume Arms

1. Improved Worker Safety

By efficiently capturing harmful fumes and dust, these arms significantly reduce the risk of respiratory issues, chemical exposure, and other health-related problems, creating a safer work environment for employees.

2. Enhanced Cleanliness and Hygiene

The smooth, non-porous surface of stainless steel is easy to clean and sanitize, making these fume arms ideal for controlled environments like cleanrooms, laboratories, and food manufacturing facilities, where hygiene is essential.

3. Cost-Effective Solution

The durability and corrosion resistance of stainless steel ensure a long lifespan for IAP fume extraction arms. Their low-maintenance design reduces operational costs and the need for frequent replacements, making them a cost-effective solution in the long term.

4. Increased Productivity

The adjustable and flexible design allows for easy positioning, ensuring the arms can capture contaminants with minimal interference. This enhances productivity, as workers can focus on their tasks without concerns about air quality or equipment issues.

Conclusion

IAP Stainless Steel Fume Extraction Arms provide a versatile, durable, and effective solution for managing fumes and dust across a variety of industries. Whether it’s ensuring compliance in pharmaceutical settings or maintaining air quality in laboratories, these fume arms offer reliable performance. Their efficient extraction capabilities, durable construction, and ability to meet regulatory standards make them an invaluable tool for ensuring a safer, cleaner, and more productive work environment.

SHARE THIS POST