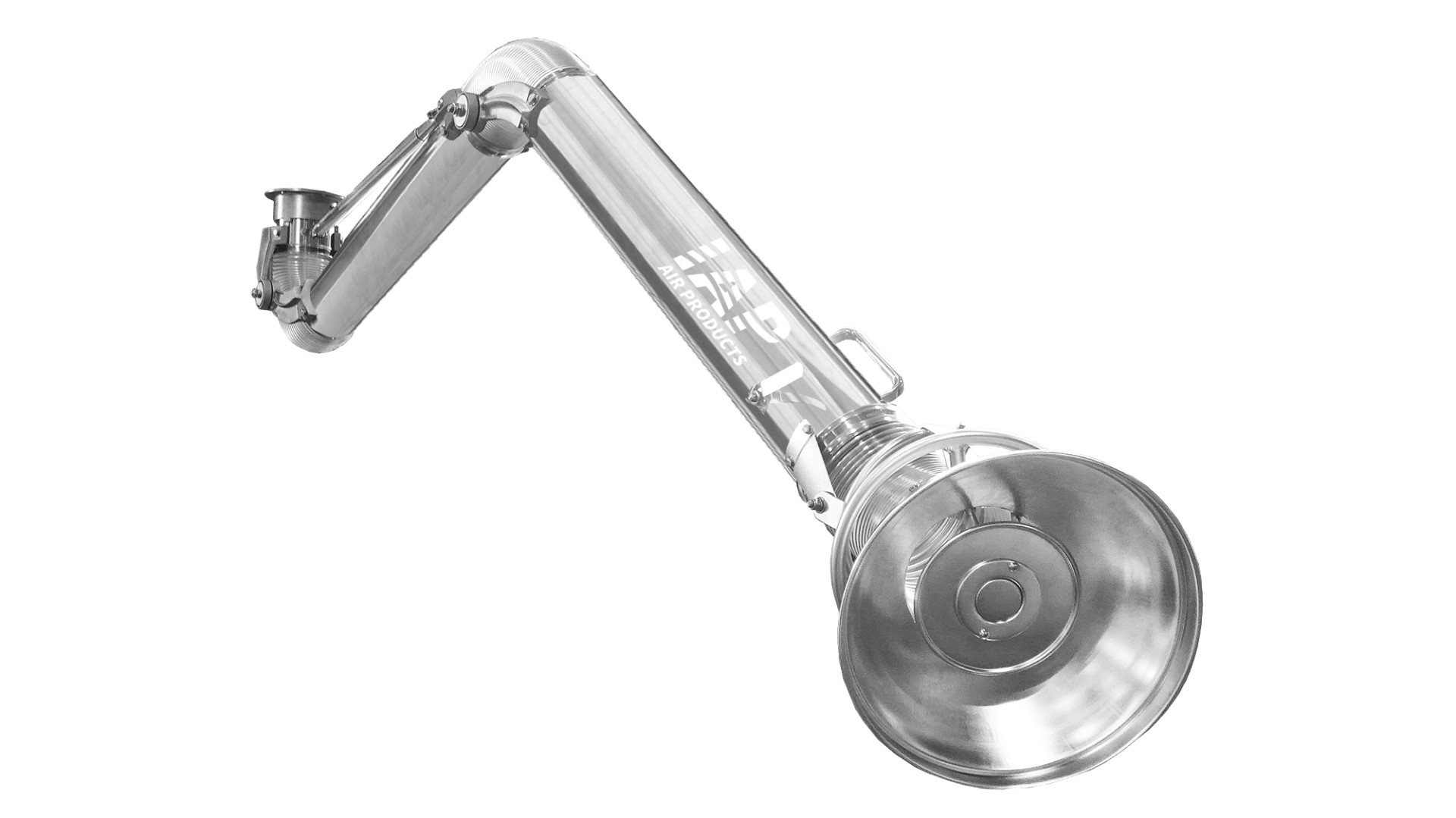

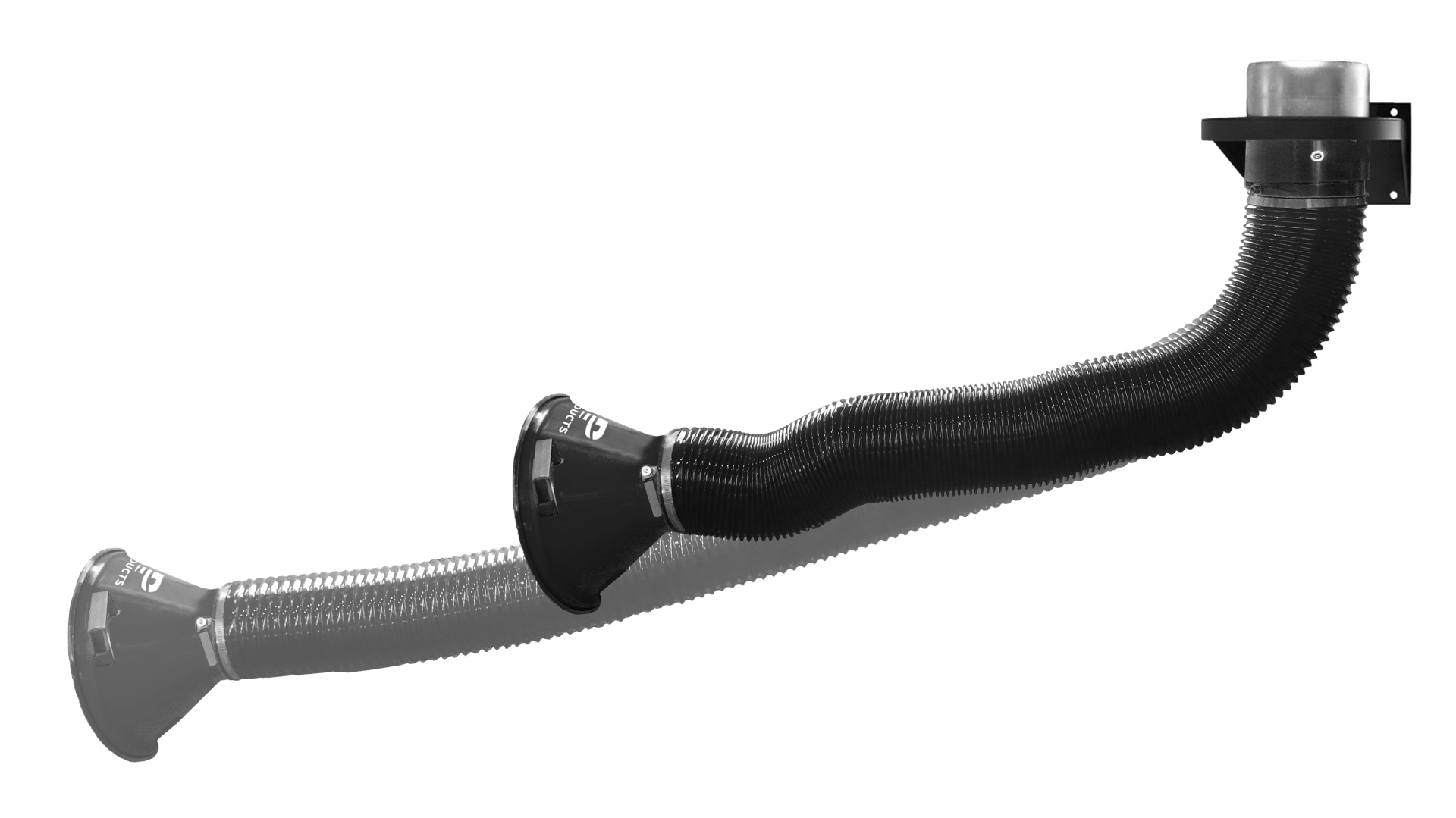

IAP Air Products offers a full line of Welding Fume Extraction Arms / Snorkels that can be utilized to safely control process fumes, dust, and smoke. Extraction Arms / Snorkels are specially designed for working environments with fumes, light dust, and smoke; where source capture is desired before the contamination has spread into the work environment and could be inhaled. The applications can be welding, grinding, or other industrial processes where an easily positioned welding fume extraction arm is required.

Welding Fume Extraction

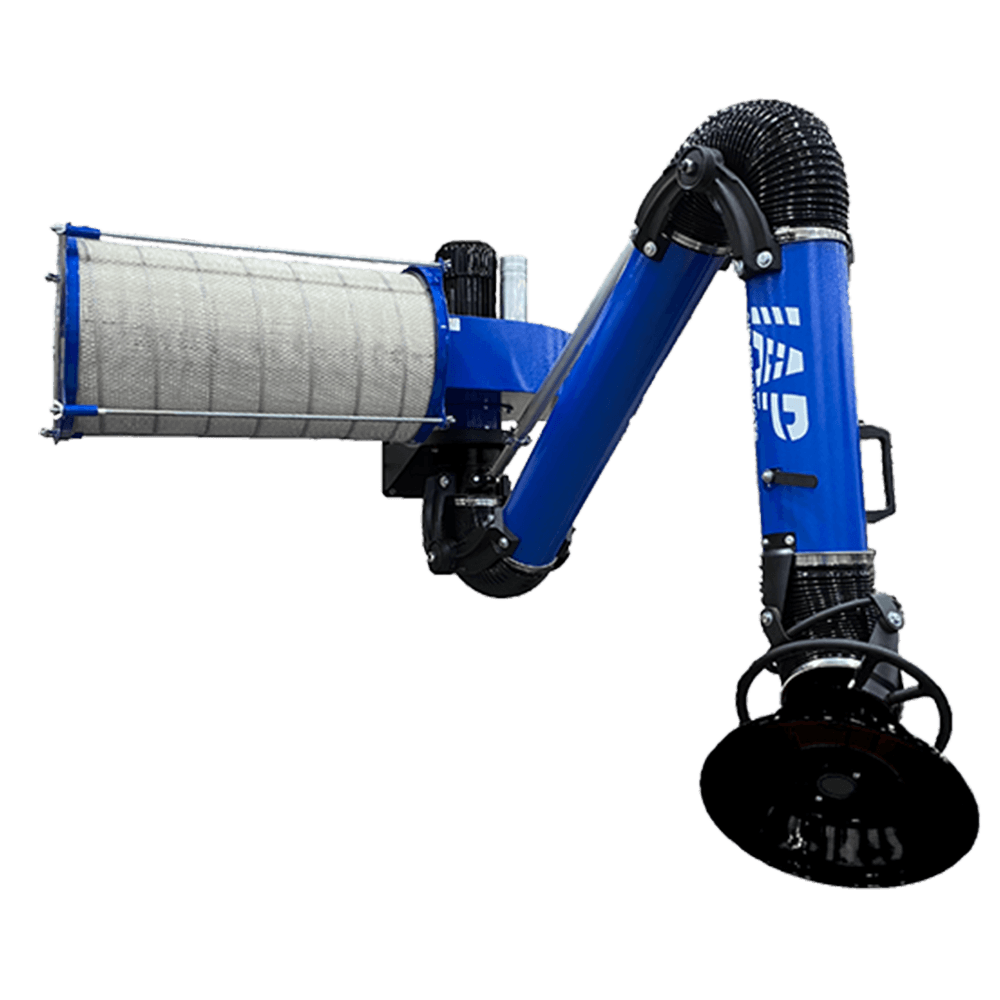

Add a filter to a direct mount fan and hanging fume arm and you have a total welding fume extraction solution. Our filtration kits are small dust collectors. They are a perfect option if you do not need a big collector or if you just don't want to spend the money on one.

What are WELDING fume extraction arms?

Welding Fume Extraction Arms are utilized in a wide range of industries and other industrial applications. You may see fume arms used by welders, chemists,woodworkers or in even in factories.

Industrial Air Purification Systems

Regardless of the system, capturing fumes at the source is the only effective way to eliminate health hazards, and Extraction Arms / Snorkels are the most common products. Whenever possible, capturing and controlling at the source is the recommended approach. Source capture involves utilizing hoods to extract the contamination at or near the generation source to protect the worker and prevent the contamination from migrating elsewhere in the facility. Source capture is the most effective means of capture and requires the least amount of energy and initial investment to accomplish. Source capture can be accomplished utilizing Welding Fume Extraction Arms / Snorkels.

Typical workplaces can be:

- Industrial Processes

- Schools, including technical, welding, automotive, etc.

- Maintenance work areas

- Powder dumping applications

- Blending applications

- Oil Mist

- Hoods that need to be moved in and out frequently

Welding Fume Extraction Arms / Snorkels can be mounted on a wall, column, I-Beam, or can be mounted on a workbench. Any location requires a sturdy structure, or supplemental supports may be required to support the counterweight of the Arms. Additionally, they can be mounted to booms, rails, or filtration boxes. Fans can be mounted directly on top of the Arms for single use applications, or they can be tied to a central ductwork system and then filtered through a dust/fume collector or exhausted outside.

Welding Fume Extraction Arms / Snorkels vary in diameter based upon air volume from 3” to 8” (350 cfm to 1000 cfm). The Arms vary in length from 5’ to 14’ and are equipped with a high efficiency extraction hood. They are designed to move smoothly and easily into position to extract contaminated air from a worker’s breathing zone. They are durable, robust and virtually maintenance free. The Extraction Arms / Snorkels are self-supporting with smooth, low-friction control and require the least maintenance of any Arms on the market today.

Benefits of Welding Fume Extraction Arms / Snorkels, include:

- The Arms is flexible in all directions and simple to position

- Designed for wall mounting or table top mounting

- Allows rotation of 180 degrees or more

- Equipped with an internal damper near the hood

- The hood can be tilted in all directions

- Smooth tube or flexible hose outer shell

- Low maintenance

- Employee friendly

- Won’t obstruct equipment for tooling changes or parts removal

For longer reach applications and where overhead cranes can restrict the installation of ductwork, swing boom Arms are provided in conjunction with an Arms. These swing boom Arms will reach from 18’ to 35’. With very little force, an operator can swing the whole set up from left to right.

For long distances applications, rails are provided with an Arms attached to a trolley. These rail type systems come in endless lengths as they are joined by splice kits. Once again, an operator can move the Arms with very little force.

Why should you use IAP fume arms?

They are high quality

All fume extractor arms from IAP are made with the highest quality and heavy duty material around. Our powder coated steel is built to handle the toughest work environments. We offer hanging, standing, telescopic, and stainless steel fume extraction arms. We also guarantee high efficiency with every IAP - Air Product. It’s important to keep your work environment clean so that your employees breathing zone is clear. You can trust us for your fume extraction needs.

We keep them in stock

We have a warehouse full of fume extraction systems. We keep our fume arms in stock so that you can receive your product as quickly as possible. We pride ourselves in being one of the fastest shippers in the industry. We are the largest stocking fume arm supplier in the U.S. with over 2000 fume arms and other products in stock. Each product that we ship undergoes a hands on quality check by our team before it leaves our warehouse.

We have a dedicated sales staff

We pride ourselves in our amazing staff. We offer better customer support than any fume arm supplier in the U.S. We are centrally located, so shipping costs are less than some of our competitors. Not only do you have quick access to our sales staff, but they have extensive freight knowledge and can get you the best possible freight service to meet your needs.

There are many applications

Our extraction arms are designed specifically for source capture of all types of fume and dust, welding fume control, soldering fumes, powder filing, maintenance welding, fume extraction in elevated spaces, particulate and fume control, chemical fume extraction, solvent and epoxy fume control, light grinding, stainless steel tank welding, and VOC removal.

For many industries

Our fume extractors meet the requirements to fulfill the needs of many industries. Laser engraving, laser printing, welding, fabrication shops, chemical, paint, solvent, laboratory, soldering, and art conservation industries all fall within the realm of use for our fume extractors. We also sell portable fume extractors and accessories to have wall mounted fume arms.