Frequently Asked Questions - CFM

How to calculate the required CFM of a weld/fume hood

Here at IAP, we get asked many questions about welding fume extraction. Recently, we have had several questions regarding how to calculate the required CFM of a welding fume extraction hood so we thought we would take the time and share an explanation!

Units:

Fume Hood Airflow - Cubic Feet per Minute (CFM)

Face Velocity - Feet Per Minute (FPM)

Calculation Explained:

The calculation for the CFM of a fume hood is obtained by multiplying the FACE OPENING (window of the fume hood) and the FACE VELOCITY.

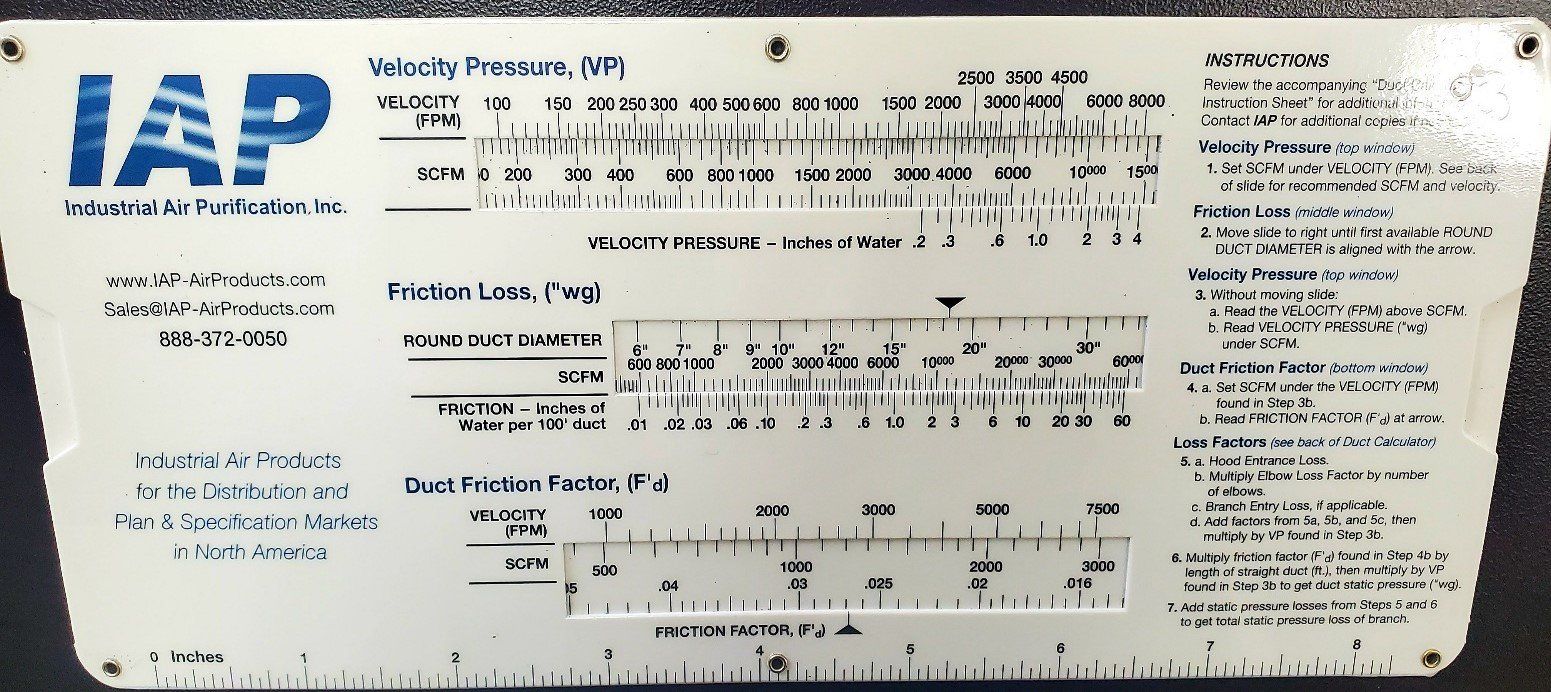

The FACE OPENING value is the maximal open Width x Height for your fume hood, while FACE VELOCITY references the usual FPM for a typical capturing process. For instance, the typical FPM for capturing welding fume extraction is 50-100 while the typical process for grinding is 500-2000 or even higher! This information can be found on the back of Slides Rules (Ductulators). The main picture shows one of these Ductulators. IAP can provide one, call Joshua and he can arrange to have one sent out.

Note: For this sample calculation we are using a hood which is 22" wide by 12" long being used to capture welding fume extraction. We will use 100 FPM for the FACE VELOCITY since we are capturing welding fumes.

FACE OPENING Calculation:

22” x 12” = 264 square inches. Divide this by 144 to get square feet.

264 ÷ 144 = 1.83 square foot opening

You would now multiply this area measurement (1.83 square feet) by your desired FACE VELOCITY, in this case 100 FPM and that will give you the CFM requirements you need.

1.8 square feet x 100 FPM = 180 CFM

So in this case, you would need your exhaust fan to be able to draw 180 CFM.

**** If your Fume Hood is already in square feet (i.e 2’x1’) you can simply multiply 2x1 = 2. You would then multiply 2 x 100 FPM to get 200 CFM needed. However, if your Fume Hood dimensions are not in square feet, it’s best to convert both dimensions to inches and proceed as the above example instructs****

SHARE THIS POST