Maximizing Weld Fume Extraction Arms

Unveiling the Benefits of Essential Accessories

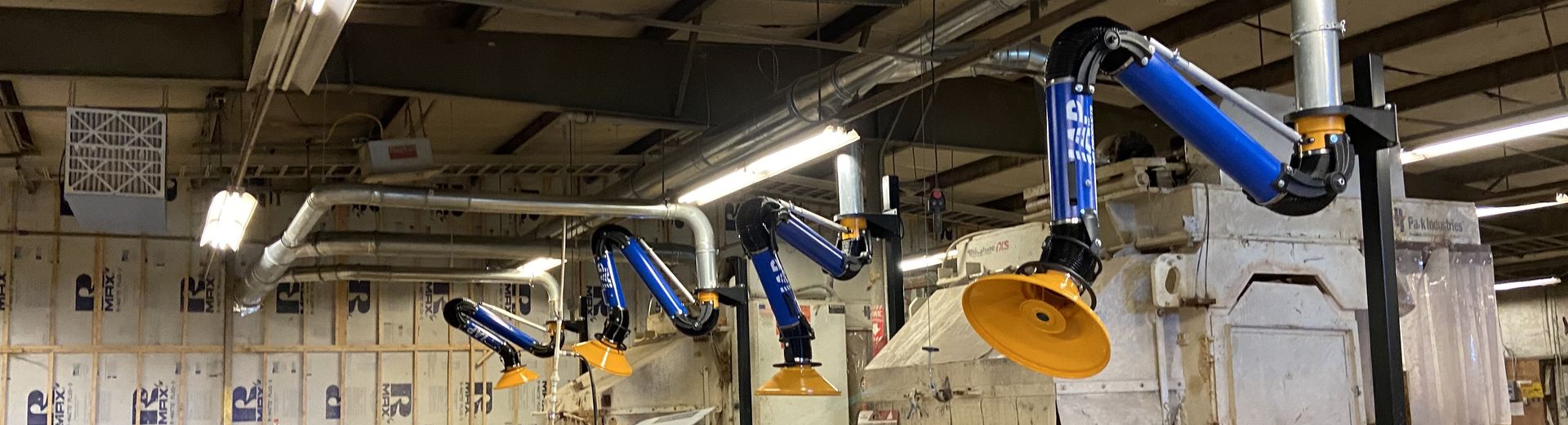

In industrial settings where the air is thick with fumes and contaminants, the importance of efficient weld fume extraction cannot be overstated. Weld fume extraction arms play a crucial role in maintaining a healthy work environment, and their effectiveness can be significantly enhanced with the use of essential accessories. In this article, we explore the perks of integrating accessories like Larger Hood, Spark Protector, High Temp Hose, Grounding Kits, and Light Kits into weld fume extraction systems.

1. Larger Hood: Expanding Reach and Efficiency

The addition of a Larger Hood to a weld fume extraction arm extends its reach and enhances its efficiency. A larger hood ensures a broader coverage area for capturing fumes, smoke, and particulate matter. This means that even in situations where the source of contamination is widespread or located in hard-to-reach areas, the larger hood provides a more comprehensive and effective solution. Improved coverage not only enhances the overall performance of the weld fume extraction system but also contributes to a safer and cleaner workplace.

2. Spark Protector: Mitigating Fire Hazards

In environments where sparks and hot particles are common, a Spark Protector is a valuable accessory. This component acts as a barrier, preventing potentially dangerous sparks from entering the weld fume extraction system. By minimizing the risk of fire hazards, the Spark Protector adds an extra layer of safety to the workplace. Industries such as welding, metal cutting, or any process involving high temperatures can benefit significantly from this accessory, ensuring a secure working environment and reducing the likelihood of accidents.

3. High Temp Hose: Durability in Extreme Conditions

Weld fume extraction arms are often subjected to high temperatures in various industrial processes. The integration of a High Temp Hose ensures the durability and longevity of the system under extreme conditions. This accessory is designed to withstand elevated temperatures without compromising its structural integrity. It not only contributes to the overall reliability of the weld fume extraction arm but also minimizes the need for frequent maintenance and replacements, resulting in cost savings over time.

4. Grounding Kits: Preventing Electrostatic Discharges

In industries where the extraction of volatile materials is common, the risk of electrostatic discharges poses a potential threat. Grounding Kits are essential accessories that help dissipate static electricity, preventing sparks that could lead to ignition in flammable atmospheres. By grounding the weld fume extraction arm, these kits contribute to a safer work environment, especially in settings where explosive materials are present. The inclusion of grounding kits is a proactive measure that aligns with industry standards for safety and regulatory compliance.

5. Light Kits: Illuminating Workspaces for Precision and Safety

The addition of Light Kits to weld fume extraction arms brings a new dimension to workplace functionality. These kits provide targeted illumination directly at the extraction point, ensuring that operators have a clear view of their work area. In environments where precision is crucial, such as laboratories or manufacturing processes with intricate details, the added visibility can enhance both safety and productivity. Light Kits contribute to reducing errors, improving work quality, and creating a well-lit workspace, ultimately fostering a more efficient and secure working environment.

Conclusion: Enhancing Safety, Efficiency, and Visibility

Incorporating accessories like Larger Hood, Spark Protector, High Temp Hose, Grounding Kits, and Light Kits into weld fume extraction arms goes beyond mere customization—it is a strategic investment in workplace safety, operational efficiency, and enhanced visibility. These accessories collectively contribute to a weld fume extraction system that is not only powerful and reliable but also tailored to meet the specific challenges of diverse industrial environments. As industries continue to prioritize employee well-being and regulatory compliance, these accessories, including Light Kits, prove to be indispensable components in the pursuit of a cleaner, safer, and more productive workplace.

For more information, contact IAP-AirProducts.

SHARE THIS POST